Internal inspection is a critical process used to examine the inside of industrial assets. It allows inspectors to assess the internal condition of structures, ensuring they remain safe and functional over time. Alongside external inspections, internal inspections form a comprehensive approach to asset evaluation. These inspections help identify potential issues that could lead to failures, safety hazards, or costly repairs if left unaddressed. Internal inspections are sometimes referred to as interior or inner inspections. They can be conducted using various methods, depending on the size, complexity, and accessibility of the asset being inspected. Traditionally, internal visual inspections required inspectors to enter confined spaces manually, which posed significant risks. However, with advancements in technology, remote solutions such as drones and robotic systems have become increasingly popular. For example, Flyability’s indoor drones allow inspectors to gather detailed visual data from within hazardous environments without putting themselves at risk. By performing internal inspections, engineers and maintenance teams can maintain the integrity of equipment, prevent accidents, and extend the lifespan of critical infrastructure. These inspections are especially important in industries where failure could result in severe consequences. In addition to visual checks, inspectors may use non-destructive testing (NDT) methods to gather more detailed information about the internal structure of an asset. This ensures a thorough assessment and helps in making informed decisions about maintenance and repair. [Internal inspections are just one area in which inspectors use non-destructive (NDT) testing methods. Learn more about NDT and the other scenarios in which it is performed in this guide.] There are several approaches to conducting interior inspections, each with its own advantages and limitations. The most common methods include: The goal of all these methods is to collect accurate and reliable data about the internal condition of an asset. Depending on the situation, inspectors may choose one method or combine multiple techniques to ensure complete coverage. With scaffolding and rope access, inspectors physically enter the space to perform their evaluations. In contrast, RVI tools like drones allow for remote inspections, reducing risk and increasing efficiency. Scaffolding is often used when access to the interior of an asset is limited or requires physical presence. It provides a stable platform for inspectors to move around and visually inspect the internal surfaces. However, scaffolding is one of the most expensive and time-consuming methods. Setting up and dismantling scaffolding can cause extended downtime, which affects productivity and increases costs. Despite this, it remains a widely used technique in many industries. Learn more about scaffolding and all its uses in our in-depth guide. Internal rope access is a specialized technique used for inspecting high or hard-to-reach areas. It involves trained technicians using ropes and safety equipment to navigate inside large industrial structures such as boilers, tanks, and pressure vessels. This method offers greater flexibility than scaffolding and reduces the need for extensive setup. However, it requires highly skilled personnel who are certified in rope access techniques. It is also considered safer than traditional methods in certain situations. Learn more about rope access in our in-depth guide. Using remote visual inspection (RVI) tools, such as drones, has revolutionized internal inspections. These tools allow inspectors to gather visual data without entering dangerous or confined spaces, significantly improving safety and efficiency. Drones like Flyability’s Elios 3 are designed to operate in tight, complex environments, collecting high-quality images and video. By eliminating the need for scaffolding and manual entry, RVI tools reduce downtime and lower operational costs. Additionally, they help companies avoid insurance risks associated with human exposure to hazardous conditions. Learn more about inspection tools in our in-depth guide. During internal inspections, inspectors typically aim to answer three key questions using non-destructive testing (NDT) methods: The first step in any internal inspection is to determine whether defects exist. Inspectors document these findings and maintain a historical record of the asset’s condition over time. This helps track changes and predict future maintenance needs. Identifying the location of a defect is crucial for effective maintenance. However, this can be challenging when using RVI tools, especially in environments where GPS signals are unavailable. Inspectors often rely on barometric measurements, blueprints, and reference points from video footage to locate defects accurately. New software tools, such as Flyability’s Inspector 3.0, help improve precision by generating sparse point clouds that show exactly where defects are found. This data can then be shared with other stakeholders, such as maintenance teams or site managers. Knowing the size of a defect is essential for determining the next steps in maintenance. It helps engineers decide whether further inspection, monitoring, or repair is necessary. Accurate measurements can prevent unnecessary work and ensure timely interventions. Internal inspections are vital across a wide range of industries, particularly those involving large, complex, or hazardous equipment. Even small defects can lead to serious safety issues if not detected early. Some of the key industries that rely on internal inspections include: Common assets that require internal inspections include: Aluminum Silicon Alloy Section Machine Aluminum Silicon Alloy Section Machine,Aluminum Wire Cutting Machine,Circular Wire Cutting Machine,Aluminum Profile Cutting Machine Changzhou Kuaile Technology Co., Ltd , https://www.quartzglasssectionmachine.comWhat Is an Internal Inspection?

Ways To Conduct An Interior Inspection

Scaffolding

Internal Rope Access

Remote Visual Inspection Tools

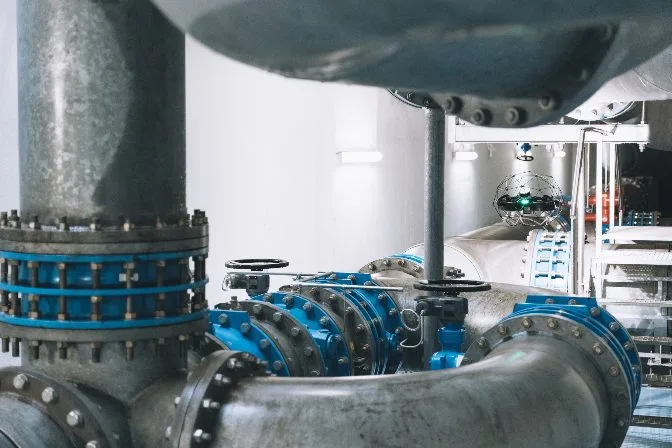

The Elios 3 performing an inspection at a water department

The Elios 3 performing an inspection at a water departmentThree Questions Inspectors Must Answer When Conducting Internal Inspections

1. Are there any defect(s) in the asset?

2. Where are the defect(s) located?

3. What are the dimensions of the defect(s)?

Industries & Assets That Require Internal Inspections

July 14, 2025