Internal inspection refers to the process of examining the inside of a structure or asset to evaluate its condition and identify any potential issues. It is a critical part of the overall inspection process, often conducted alongside external inspections to ensure that all areas are thoroughly reviewed. Also known as interior or inner inspection, this type of assessment helps determine if there are any defects, wear, or damage within the asset that may require further action. Traditionally, internal inspections were carried out by inspectors entering confined spaces manually, but recent advancements in technology have introduced safer and more efficient alternatives. For example, drones like Flyability’s Elios 3 now allow inspectors to remotely access hard-to-reach areas without putting themselves at risk. This not only improves safety but also reduces downtime and costs associated with traditional methods such as scaffolding or rope access. Internal inspections are commonly used in industries where the integrity of equipment and structures is essential for safety and operational efficiency. They help prevent failures, reduce risks, and ensure compliance with industry standards. In addition to visual assessments, inspectors may use non-destructive testing (NDT) methods during internal inspections to gather more detailed data about the condition of the asset. These techniques allow for accurate evaluations without damaging the structure being inspected. [Internal inspections are just one area in which inspectors use non-destructive (NDT) testing methods. Learn more about NDT and the other scenarios in which it is performed in this guide.] There are several methods used to conduct interior inspections, each with its own advantages and limitations. The choice of method depends on factors such as the type of asset, accessibility, and safety considerations. Each approach aims to provide inspectors with the necessary data to assess the condition of the asset. While scaffolding and rope access involve direct human involvement, RVI tools like drones allow for remote data collection, reducing the need for physical entry into hazardous environments. Scaffolding is a temporary structure built to give inspectors access to the interior of an asset. While it has been a traditional method, it can be time-consuming and expensive due to the labor required for construction and dismantling. Additionally, the downtime caused by scaffolding can impact operations and increase costs. Despite its high cost, scaffolding remains a common method for internal inspections, especially in older facilities where modern technologies are not yet adopted. Learn more about scaffolding and all its uses in our in-depth guide. Internal rope access is a technique used to inspect high or confined spaces. Certified technicians use ropes and safety systems to navigate and inspect the interior of large industrial assets such as pressure vessels, boilers, and stacks. This method is less costly than scaffolding and allows for greater flexibility in accessing tight spaces. However, it requires trained professionals who understand the risks and can perform the work safely. Learn more about rope access in our in-depth guide. Remote Visual Inspection (RVI) tools, such as drones and robotic systems, are becoming increasingly popular for internal inspections. These tools allow inspectors to collect visual data from inside an asset without physically entering it, significantly improving safety and efficiency. Drones like Flyability’s Elios 3 are designed to operate in challenging environments, such as mines, sewers, and tanks, where human entry would be dangerous. By eliminating the need for scaffolding and reducing inspection time, these tools offer significant cost savings and operational benefits. Learn more about inspection tools in our in-depth guide. During internal inspections, inspectors typically use non-destructive testing (NDT) methods to answer three key questions: The first step in an internal inspection is to identify whether any defects exist. Inspectors document these findings and maintain a historical record of the asset’s condition over time. Determining the location of a defect can be challenging, especially when using remote tools like drones. Without GPS or clear reference points, inspectors may rely on barometric measurements, blueprints, or video footage to locate defects accurately. Some advanced software, such as Flyability’s Inspector 3.0, provides a sparse point cloud that helps inspectors pinpoint the exact location of defects. This data can then be shared with maintenance teams or site managers for further action. Knowing the size of a defect is crucial for determining the next steps in maintenance. It helps decide whether the defect needs immediate repair, ongoing monitoring, or further inspection. Internal inspections are essential across various industries, as even minor defects can lead to serious consequences if left unchecked. Some of the most common sectors that rely on internal inspections include aerospace, oil and gas, power utilities, and manufacturing. Common assets that require internal inspections include boilers, pressure vessels, pipelines, tanks, and wind turbines. These structures are often complex and difficult to access, making internal inspections a vital part of their maintenance and safety protocols. By conducting regular internal inspections, companies can prevent failures, ensure compliance, and protect both personnel and infrastructure from potential hazards. Quartz Glass Section Machine,Optical Glass Breaking Machine,Optical Glass Cutting Machine,Glass Cutting Machine Changzhou Kuaile Technology Co., Ltd , https://www.quartzglasssectionmachine.comWhat Is an Internal Inspection?

Ways To Conduct An Interior Inspection

Scaffolding

Internal Rope Access

Remote Visual Inspection Tools

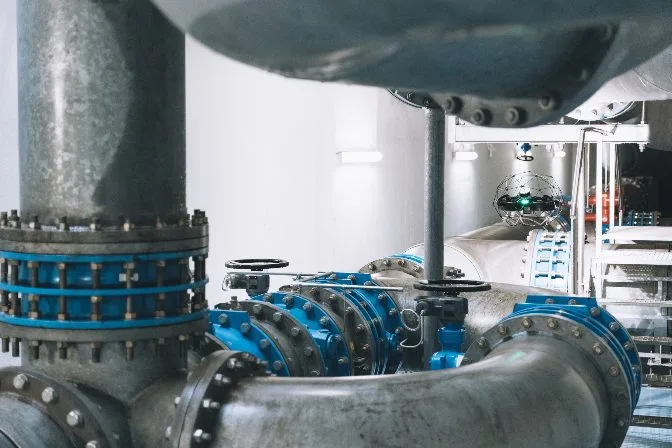

The Elios 3 performing an inspection at a water department

The Elios 3 performing an inspection at a water departmentThree Questions Inspectors Must Answer When Conducting Internal Inspections

1. Are there any defect(s) in the asset?

2. Where are the defect(s) located?

3. What are the dimensions of the defect(s)?

Industries & Assets That Require Internal Inspections

July 14, 2025