Strong Injection Molding Machine Plastic Injection Molding Machine,Precision Machine,Injection Molding Plastic Parts NINGBO HAITUO MACHINERY TECHNOLOGY CO.,LTD , https://www.china-haituo.com

Spring cleaning isn’t just for your home—it’s essential for your solar system too! After enduring harsh winter conditions like snow, ice, and rain, solar panels and equipment can suffer from wear and tear. A routine inspection and maintenance check-up ensures your system is ready to perform at its best as the warmer months approach.

**Why does this matter for owners and financiers?**

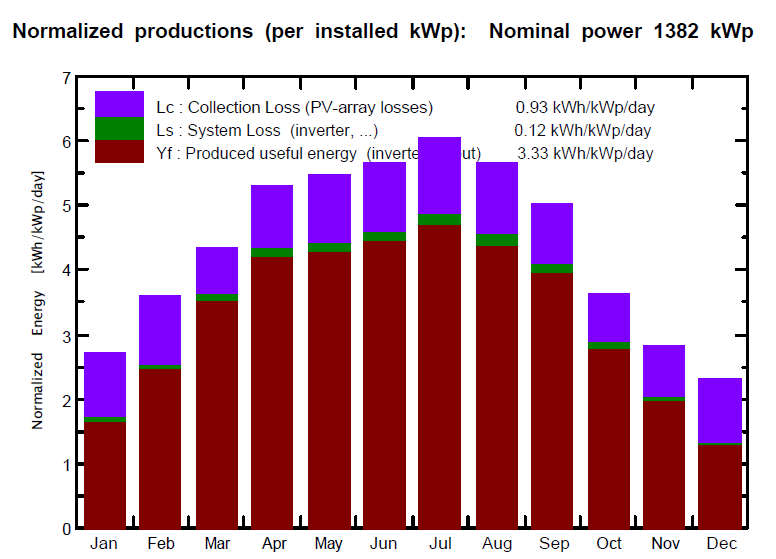

The peak generation period for solar systems typically runs from April to September. Any unexpected downtime during this time can lead to significant revenue loss for the owner. For financiers, maintaining system performance is key to ensuring long-term returns on investment.

In the Northeastern U.S., ground-mounted solar systems often experience seasonal performance fluctuations. Regular maintenance helps minimize these dips and keeps output consistent throughout the year.

**What’s included in a preventive maintenance (PM) check?**

A comprehensive PM involves several critical steps:

**Step 1 – Visual Inspection and Repair**

This initial step focuses on identifying visible issues that could impact performance or safety:

- Checking wire management for integrity—damaged wires can cause arc faults or even fires.

- Inspecting structural components for loose hardware or signs of corrosion.

- Cleaning filters on inverters and ventilated equipment to prevent overheating.

- Removing nests, debris, and pests from modules, racking, and enclosures.

- Ensuring all weather instruments are clean, functional, and properly aligned.

**Step 2 – Diagnostic Inspection and Repair**

Some problems require deeper analysis using advanced tools:

- Infrared (IR) scans of electrical connections to detect overheating and ensure proper continuity.

- Aerial IR scans of the entire solar array to identify hotspots or cold spots quickly.

- IV curve tracing to pinpoint the root cause of performance issues when IR scans only show symptoms.

**Step 3 – Performance Testing**

The final step confirms that the system is operating efficiently:

- Verifying that the data acquisition system (DAS) is reporting accurately.

- Reviewing annual performance metrics to identify any underperformance. Tools like performance ratios or regression tests help assess whether the system is meeting its expected output.

**What should you do before a PM?**

It’s best to monitor your system throughout the year to catch issues early. Monthly performance reports can help track trends and spot anomalies before they become major problems.

However, some repairs may be more cost-effective if delayed until the next scheduled PM. This approach reduces the number of service calls and lowers overall maintenance costs.

Regular maintenance not only extends the lifespan of your solar system but also maximizes energy production and financial returns. Don’t wait for a problem to arise—stay proactive and keep your system running smoothly all year round.

July 09, 2025