This article focuses on the system precision and local accuracy of 3D models generated using LiDAR data from Flyability’s Elios 3, as tested in an office environment. For insights into global and georeferenced accuracy, you can refer to our previous study conducted in a large warehouse. Note: The first two sections of this article (the Introduction and Why We Performed These Tests) are identical to those in the previously mentioned white paper. If you've already read that document, we recommend starting from the Defining Our Terms section below. In recent years, LiDAR has become a key technology for creating accurate and detailed 3D models across various industries such as mining, construction, and infrastructure. These models enable professionals to conduct inspections, track asset changes, and support project planning with greater efficiency and precision. The outputs from LiDAR-based 3D models include digital twins, precise measurements, defect detection, and the ability to export data in common formats like *.e57, *.las, *.laz, and *.ply. Merging multiple georeferenced models also helps monitor changes over time. However, the value of these models depends heavily on their quality. If the data lacks precision and accuracy—terms with specific meanings in 3D modeling—the models may not reflect real-world conditions accurately. This article presents findings from tests conducted by GeoSLAM and Flyability to evaluate the performance of the Elios 3 with GeoSLAM Connect, comparing it to leading mobile mapping systems like the ZEB Revo and ZEB Horizon. Flyability’s Elios 3 is equipped with Ouster’s OS0-32 LiDAR sensor and SLAM capabilities, allowing it to create real-time 3D models during flight. After the mission, users can process the collected data using GeoSLAM Connect to generate precise, accurate point clouds. While the 3D Live Model supports navigation and route planning, the post-processed model from GeoSLAM Connect provides higher accuracy. Combining this with the Elios 3’s collision-tolerant design makes it ideal for mapping confined spaces effectively. But questions remain about how factors like vibration, dust, or moisture might affect the quality of the final 3D models. To address these concerns, we conducted a comprehensive evaluation of system precision and local accuracy using the Elios 3 and GeoSLAM Connect in a controlled indoor setting. In 3D modeling, accuracy refers to how closely a measured value matches the true value. For example, if a measured distance of 100mm in your point cloud differs significantly from the actual distance, the model is not accurate. Accuracy ensures that the model reflects reality, including correct shapes and spatial relationships. Local accuracy, on the other hand, measures the distance between points within a single view, such as the dimensions of a room. Precision relates to the consistency of repeated measurements. If you measure the same distance five times and get the same result each time, your model is precise. However, high precision doesn’t always mean high accuracy, and vice versa. Understanding the difference between precision and accuracy is essential when selecting tools and methods for 3D mapping projects. To assess the precision and local accuracy of the Elios 3 with GeoSLAM Connect, we performed: To ensure reliable results, we used a high-accuracy Terrestrial Laser Scanner (TLS) as the control. The Riegl VZ-400, known for its 5mm accuracy at 1-sigma, served as the benchmark for our tests. Data was collected from a planar indoor environment using both the Elios 3 and the Riegl VZ-400. The reference model was created from the TLS data, providing a reliable ground truth for comparison. We aligned the Elios 3 point cloud to the reference model using PolyWorks|Inspector MRS2019 IR3. This involved manual alignment followed by an automated Best-Fit transformation to minimize deviations. By fitting planes to both the Elios 3 data and the reference model, we calculated the Normal Distance between them. This provided insight into the local accuracy of the point cloud. Range Noise was calculated by measuring the deviation of individual points from the mean within selected planar areas. This gave us a clear indication of the system’s precision. The tests were conducted in a standard office space with six planar surfaces, each approximately 1 meter square. These surfaces were strategically placed to ensure comprehensive coverage of the area. Here are the results of the assessments: The Plane-to-Plane analysis revealed that the mean absolute normal distance between the Elios 3 model and the reference model was 8mm (.32 inches), with all comparisons falling within +/- 16mm (.63 inches). The Range Noise analysis showed a mean standard deviation of 8mm (.32 inches) to 1-sigma, indicating that the system maintains consistent accuracy across different test areas. These results confirm that the Elios 3 with GeoSLAM Connect delivers reliable performance, comparable to traditional TLS systems and other leading mobile mapping solutions. Conclusion Through rigorous testing in a controlled office environment, the Elios 3 with GeoSLAM Connect demonstrated strong system precision and local accuracy. Compared to a high-accuracy Riegl VZ-400 TLS, the results show that the Elios 3 can produce reliable 3D models suitable for professional applications. 1: Pure electric drive electric bus

6:The length of the bus is between 3m and 7m

7:Mini seats (qty): 5 seats to Max seats (qty) 32 seats

Electric Mini Bus,Electric Shuttle Bus,Electric Sprinter Bus,Electric Sprinter Van MAIN NEW ENERGY CO.,LTD , https://www.main-newenergy.comTEST RESULTS OVERVIEW

Introduction

Why We Performed These Tests

Defining Our Terms: Precision and Local Accuracy in 3D Mapping

System Precision and Local Accuracy Assessments with the Elios 3

Establishing a Control

Collecting the Data

Aligning the Elios 3 Point Cloud to the Reference Model

Assessing Local Accuracy—Plane-to-Plane Comparison

Assessing System Precision—Range Noise Analysis

Test Environment

System Precision and Local Accuracy Test Results

Assessing Local Accuracy

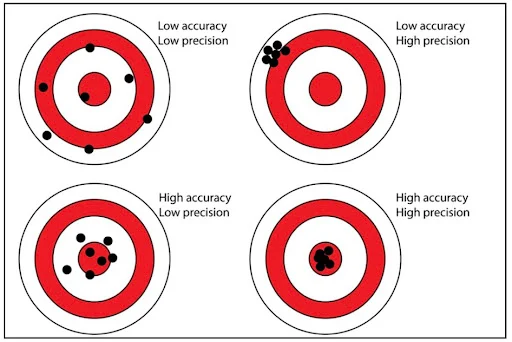

Accurate measurements fall in the bullseye. Precise measurements are tightly clustered.

Accurate measurements fall in the bullseye. Precise measurements are tightly clustered.Assessing System Precision

2:Automatic transmission

3:Lithium iron phosphate power battery, safe and sufficient power

4:Mileage: 200km-500km after charge

5:Environmental protection, no pollution, minimal noise

June 30, 2025