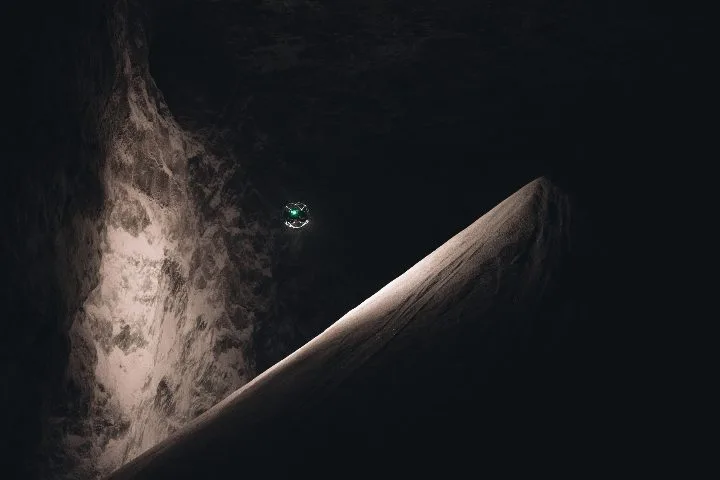

At a salt mine in Germany, engineers turned to the Elios 3 drone to improve the accuracy and efficiency of stockpile measurements. This cutting-edge tool, equipped with a LiDAR sensor and powered by Flyability's advanced SLAM technology, proved invaluable in streamlining operations and ensuring worker safety. Efficiency Manually measuring stockpiles is labor-intensive and time-consuming. With the Elios 3, surveyors can cover large areas swiftly by flying the drone from a single point, generating precise 3D models in minutes. Precision Compared to traditional manual methods, the Elios 3 delivers higher accuracy in stockpile measurements. Its LiDAR technology ensures reliable data, reducing errors and improving decision-making. Safety Surveying salt stockpiles manually involves climbing steep surfaces, posing risks of accidents. The Elios 3 eliminates this danger by allowing operators to stay grounded while collecting comprehensive data. Volume calculations are fundamental in mining operations, helping estimate the amount of material stored, monitor changes, and plan for future extraction. Traditionally, these calculations rely heavily on manual methods, which are inefficient and prone to inaccuracies. The Elios 3 offers a modern solution to these longstanding challenges. Currently, surveyors typically climb stockpiles to take measurements, a process that is both time-consuming and risky. Additionally, relying on manual sensors and truck weights introduces further uncertainty into the equation. These limitations necessitate a smarter approach, one that the Elios 3 provides. At the salt mine in question, the surveying team plays a crucial role in maintaining an inventory of the mine's resources. Monthly surveys of the salt stockpiles are essential for this purpose. However, these surveys are resource-intensive, requiring two full shifts—one for data collection via manual climbing and another for subsequent calculations. During the data collection phase, surveyors climb the salt piles to measure heights and then transfer this information into CAD software for volume estimations. While effective, this method is exhausting and prone to human error. There was clearly a need for a more efficient and safer alternative. When the mine's engineers learned about the Elios 3, they saw an opportunity to revolutionize their measurement processes. Equipped with a LiDAR sensor and FlyAware technology, the drone promised to deliver fast, accurate, and safe data collection. The surveying team decided to trial the Elios 3 to assess its potential. The goal was straightforward: to replace the manual process with a drone-based system that would generate detailed 3D models of the stockpiles. This would not only save time but also ensure greater precision and reduce the risk of injury during data collection. The trial exceeded expectations. Using the Elios 3, surveyors were able to capture high-quality 3D models of multiple stockpiles in a fraction of the time required by manual methods. The following benefits were observed: “Before this, I had no experience with drones, but the Elios 3 made everything straightforward. It’s incredibly stable and easy to control,†remarked a mining engineer involved in the trial. Based on the successful trial, the surveying team is enthusiastic about adopting the Elios 3 for all future volume calculations. This shift promises substantial improvements in efficiency, data quality, and operational safety. By integrating the Elios 3 into their workflows, the mine can enhance its understanding of the entire operation. Beyond stockpile measurements, the drone could be used to map the entire mine, creating detailed 3D models that surpass the capabilities of existing 2D plans. As the head of the surveying department noted, “The Elios 3 opens new possibilities for us. Not only does it improve our current processes, but it also gives us the tools to explore the mine in ways we couldn’t before.â€

Floated type shell&tube heat exchanger is mostly used for large temperature fluctuations and temperature differences, compared with Fixed Tube Heat Exchanger, its structure is more complex and more expensive.

One end of the tube is fixed on an immobile Tube Sheet, which is clamped between the shell Flange and the tube flange, and is connected by bolts; the other end of the tube is fixed on a floating head tube sheet, which is clamped between the floating cover and the hook ring connected by studs, forming a floating head that can move freely in the shell.

If the tube bundle and the shell are heated and elongated, they do not affect each other, so there is no temperature difference stress. The floating part is a detachable connection consisting of the floating tube sheet, hook ring and floating cover. It is easier to take the tube bundle out, and the tube can be cleaned both inside and outside and is easy access.

Floating Head Heat Exchanger,Floating Head Exchanger,Floating Head Type Heat Exchanger,Floating Tubesheet Heat Exchanger Guangdong Jiema Energy Saving Technology Co.,Ltd , https://www.jmheatexchanger.comEnhancing Efficiency and Safety with Elios 3 at a German Salt Mine

In a Nutshell: The Benefits

Introduction

Customer Needs

Solution

Results

Conclusion

June 19, 2025