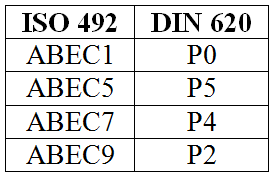

Table 1. Corresponding ISO and DIN precision standards Hudeng Metal Materials Co., Ltd , https://www.hudengmetal.com

hbspt.cta._relativeUrls=true;hbspt.cta.load(427283, '2e1e4888-ceee-4597-b4a6-2b7b751c9cc7', {"useNewLoader":"true","region":"na1"});

---

This version maintains the core message while improving flow, readability, and length.

hbspt.cta._relativeUrls=true;hbspt.cta.load(427283, '2e1e4888-ceee-4597-b4a6-2b7b751c9cc7', {"useNewLoader":"true","region":"na1"});

---

This version maintains the core message while improving flow, readability, and length.

Sure! Here's the rewritten content in English:

---

Have you ever found yourself staring at a bearing catalog and feeling completely lost, especially when faced with those mysterious codes and letters that seem to define bearing tolerances? At Emerson Bearing, we understand that understanding these terms can feel like learning a new language. That’s why we’ve put together this guide to help you break down the jargon and select the perfect bearing for your needs.

The fundamental structure of a bearing includes an inner ring with a specific thickness, an outer ring with its own defined thickness, and rolling elements that fit snugly between them. These components adhere to strict standards set by ISO 492 and DIN 620. Bearing tolerances can generally be grouped into three categories: **dimensional accuracy**, **form accuracy**, and **running accuracy**.

**Dimensional accuracy** focuses on the outer dimensions of the bearing. Different letters represent varying dimensions, such as:

- **Inner ring bore diameter (d)**: This is the diameter of the inner ring.

- **Outer ring diameter (D)**: The size of the outer ring.

- **Inner ring width (B)**: The thickness of the inner ring.

- **Outer ring width (C)**: The thickness of the outer ring.

The tolerances within dimensional accuracy measure the variance between the intended size and the actual measurement. These measurements are typically taken in one plane. Symbols like dmp and Dmp denote the mean bore and outer diameter tolerances, respectively.

**Form tolerances**, represented by the letter V, ensure that the bearing maintains its ideal shape during operation. For example, the maximum variation in the mean bore and outer diameter tolerances are marked as Vdmp and VDmp. Both dimensional and form tolerances play a critical role in ensuring proper fits for the bearing's housing and shaft.

**Running accuracy** pertains to how well the bearing performs under operational conditions. This includes factors like radial and axial runout, as well as inner and outer ring side runout (denoted as Kia and Kea, respectively). When designing your machinery, it’s essential to consider these running accuracy tolerances to reduce vibrations and prevent misalignments.

Bearings are classified based on their level of precision. While standard bearings (ABEC1/P0) suffice for most applications, specialized equipment like machine tools or precision instruments often require bearings with tighter tolerances to ensure smooth operation, high speed, and accuracy.

The precision of a bearing is determined by its tolerance class. Under ISO 492 standards, a higher number indicates greater precision. Conversely, under DIN 620 standards, a lower number signifies higher precision (with the exception of the standard tolerance, P0). Table 1 outlines the correspondence between ISO and DIN precision standards in ascending order.

June 02, 2025